Most buildings need a strong and solid foundation. Not only does a good foundation help keep your building in place, but it also helps protect against flooding and costly repairs. As a vital component for the structural integrity of your building, it’s almost as important as the structure itself.

There are different types of foundations for different buildings and sizes. While the type depends heavily on your plans for using the space, other factors like climate and geographical location also play a role in the ideal foundation.

In this article, we’ll explore a few types of foundations to consider for your building, the benefits of each, and which is best for your construction project.

Concrete Slab Foundation

Also known as “slab-on-grade” foundations and “monolithic” concrete pads, these are flat slabs of concrete poured into one single piece on the ground. Newly poured concrete takes about twenty-eight days to fully cure, but it’s strong enough to start framing about a week after installation.

Concrete slab foundations have a simple and fairly quick installation process and are one of the most common choices for carports and garages. Concrete is also fire and termite-resistant, making it a long-lasting and reliable option.

The average concrete slab has a thickness of four to eight inches, depending on your local building codes. For heavier vehicles, such as for parking RVs, requirements for slabs may be up to six inches thick.

Benefits:

- Low-cost

- Durable base for heavy structures and parking vehicles

Drawbacks:

- Not ideal for climates where the ground can freeze and thaw (can cause the slabs to crack and shift)

- Have to handle sewage and drainage pipes before slab installation (have to cut into the slab to fix them if problems arise)

Concrete slab specs to know:

- Thickness: At least four inches, suitable for most garages.

- Size: Recommended twelve inches wider and twelve inches longer than the base of the garage, varies by location, use our concrete pad size calculator to determine right size for property.

- Slope: Should be completely level, especially for detached garages.

- Edges: Recommended to slope the outer edges of the pad three-fourths of an inch lower than the top of the pad to prevent rain water from pooling.

- Footings: Must be thicker than the remainder of slab to support garage walls, usually required one foot deep and one foot wide.

Wood Foundation

Wood may not be as strong as solid concrete but it carries other qualities that make it a reputable foundation choice. While regular wood is prone to termites, mold, and decay, the preservative agents in pressure-treated lumber, such as chromated copper arsenate (CCA) can withstand them all.

Pressure-treated wood foundations became popular around the 1960s, where the beams are generally placed on gravel or atop concrete masonry blocks to create crawl space. What’s notable about wood foundation is its quick and simple installation process, which is fairly easy for a woodworker or DIY enthusiast.

Wood is also a natural insulator, helping keep the interior structure warm and less drafts in crawl spaces. Buildings with a wood foundation consume less energy than those with concrete base, making them ideal for spaces where you plan to spend a lot of time, like workshops.

Certain wood types, including redwood, cedar, and cypress, are naturally resistant to mold and insects, but they’re more expensive. Wood foundation also requires well-maintained dry soil, so damp and humid areas aren’t ideal.

Benefits:

- Quick and simple installation process

- Natural insulator, energy-efficient

Drawbacks:

- Tend to cost more than poured concrete (for the amount of lumber needed)

- Can be toxic during installation due to the preservatives

- Susceptible to rot and insect damage if not properly treated

Wood foundation specs to know:

- Preservation: foundation-grade pressure treatment, damp-proofing, spacing for good drainage.

- Footing: posts on solid pea gravel or concrete blocks 16x8x2 in.

- Size: 4×4-in. lumber runners.

- Stability: proper fasteners, durable studs for soil pressure, post base brackets, nails to secure panels to frames.

Stone

Originally known as foundations built entirely of large stones, stone foundations in modern construction use stone or masonry materials in combination with other materials. Stone is exceptionally durable and popular for historical restoration and projects seeking a unique design.

Stone foundations are, however, typically more expensive than concrete slabs and require skilled masons for proper construction.

Benefits:

- Durable

- Traditionally elegant design

Drawbacks:

- Expensive

- Requires skilled labor

Gravel Foundation

For portable metal buildings like mobile homes, gravel foundations are a great option. They’re also the best choice for sheds, allowing you to move or relocate it as desired. Many people choose to frame it with timber around the base, which helps keep gravel inside and can look nicer for yards and gardens.

The perks of gravel is that it’s the most affordable and readily available foundation type. Also, water drains quicker through gravel than soil and other types of foundation, making it an ideal shed foundation. With gravel, you can create better leveling, and it’s an easy DIY installation.

With that said, gravel isn’t as durable or strong as other foundation types. Gravel foundations also require mobile home anchors for carports, which may require drills and professional help to secure firmly.

Benefits:

- Cost-effective and readily available

- Easy to install and level

- Less susceptible to settling

- Good drainage

Drawbacks:

- May need frequent maintenance

- Not ideal for heavy structures (requiring anchors for security)

- Requires weed control

Gravel foundation specs to know:

- Type: Three-fourth inch stone, aka 57 Granite, Crusher Run (mix of ¾” and smaller), three-fourth inch bluestone for wet areas

- Size: Two feet wider and Two feet longer than size of shed or storage building

- Thickness: Four to six inches or more for better drainage

Pier and Beam Framing

Also known as “pier and post,” this foundation is popularly used in coastal areas and those prone to hurricanes. This is because piers elevate your building, providing structural support in case of flooding. You may recognize homes with this type of foundation as “stilt houses.”

Pier and post foundations are composed of three main elements:

- The posts (or “piles”)

- Wooden beams

- Concrete piers installed deep in the ground.

This foundation type is good for anchoring large storage buildings above the soil that constantly floods and shifts.

Not only do piers and posts protect structures from water damage, but they also prevent them from sinking. You’ll automatically have ample crawl space beneath this foundation, creating easy access to wiring and pipes. Another perk is the flexibility to build on uneven land. In the event of damage, they’re easier and cheaper to repair.

Benefits:

- Protects structures from water damage

- Suitable for uneven terrain, preventing sinking

- Easier to fix

Drawbacks:

- Require professional planning from a structural engineer for proper installment

- More expensive than concrete slabs

- Space beneath piers is susceptible to animal and insect infestation

Pier and Beam specs to know:

- Size: 8×8 in. or 12×12 in. concrete blocks, 6×6 in. treated wood posts (foundation grade)

- Footing: reinforced concrete on firm, undisturbed soil and level, at least twelve inches diameter, at least eight inches thick

- Spacing: about 18–22 inches high/crawl space

Basement Foundation

Unlike other common foundations, a basement foundation extends below the ground level, creating a partial or full underground story within a building. This foundation type creates valuable, additional living space to use for bedrooms, recreation, or storage.

Basements can provide good insulation and protection from the elements, which can be a good choice if you’re building a home or storage unit in a region with harsh weather conditions. The downside, however, is that basements are a bit more expensive due to excavation requirements. They can also flood if not waterproofed.

Benefits:

- Good insulation

- Protection from severe weather and elements

Drawbacks:

- More expensive due to excavation

- Potential flooding if not properly waterproofed

Concrete Masonry Units (CMUs)

Also known as large cinder blocks, concrete masonry units (CMUs) are held in place with mortar as another type of foundation. They’re a great option for commercial buildings, such as warehouses, especially if you’d like to add a basement for additional storage.

This is because CMUs have great compressive or “load-bearing” strength. Cinder blocks are low-cost, sustainable, and low-maintenance. Also, just as with poured concrete slab, CMUs are fire- and insect-resistant and readily available.

As for considerations, CMU foundations are not well insulated. They can be heavy to handle, so you’ll most likely need a professional company to help install them. More importantly, these blocks aren’t water-resistant, which can lead to expensive repairs down the road.

Benefits:

- Load-bearing strength for commercial buildings

- Readily available

- Fire- and insect-resistant

Drawbacks:

- Require professional installation

- Poor insulation

- Not water-resistant

CMU foundation specs to know:

- Size: 8x8x16 in. concrete blocks or larger

- Stability: vertical reinforcing bar (rebar) in holes filled with concrete

- Footings: cast-in-place concrete on undisturbed soil, beneath frost depth

Crawl Space

Last of all is a crawl space foundation, which elevates a building floor a couple of feet above the ground to create a shallow enclosure beneath the structure. This space is usually accessible through a crawl space door and provides easier access to electrical wiring, plumbing, and HVAC systems’ maintenance and repairs.

Crawl spaces are a good foundation option if you live in areas with high water levels or uneven terrain. They also are helpful in hot and humid climate regions that can benefit from air circulation under the floor. Crawl spaces can, however, be susceptible to pest problems and require proper ventilation to avoid mold growth.

Benefits:

- Creates easy access area for utility maintenance and repairs

- Helps reduce moisture levels

Drawbacks:

- Possibility of pest infestation

- Require regular maintenance for proper ventilation

Factors When Choosing a Foundation

To select the best type of foundation for your project, there are a few factors to consider beforehand:

Intended Use

How do you plan to use your building? Even a simple shed to store garden tools will most likely have construction regulations for the foundation. You’ll first need to check the local building codes and HOA guidelines of permits, frost lines, and location specs on your property, as well as underground utilities.

Size and Space

Next, the building’s dimensions, including its horizontal and vertical load, must be taken into account. A good rule of thumb is to have at least three feet of clearance around the perimeter of sheds—and even more for garages and storage buildings—to ensure enough space between fences and other structures.

Climate

The local climate, including moisture levels, weather, and wind conditions, will also affect your foundation choice. For example, concrete slabs can crack under pressure in colder regions that freeze and thaw at different times of the year.

Soil and Landscape Conditions

Lastly, you’ll want to build on an area that is close to level and doesn’t collect water. It’s best to test the quality of the soil, such as its moisture content and settlement, to determine if it supports your foundation of choice.

Frequently Asked Questions

What is the most affordable foundation type?

Concrete slabs are considered the cheapest foundation for homes and garages, which typically cost $8–$15 per square foot. However, for smaller structures like sheds, gravel foundations are cheaper at around $1.25–$1.50 per square foot.

Which foundation is best for a shed?

Since it’ll most likely be for garden supplies, mowers, and household items, a gravel foundation is best for sheds. Not only is gravel cheaper than a concrete slab, but it also promotes water drainage, protecting your storage items from water damage.

What is the difference between footing and foundation?

The footing is a portion of the foundation that actually touches the soil, providing support to the rest of the foundation from underneath and creating a safe settlement. Simply put, think of the foundation of your building as the “legs” and the footing as the “feet.”

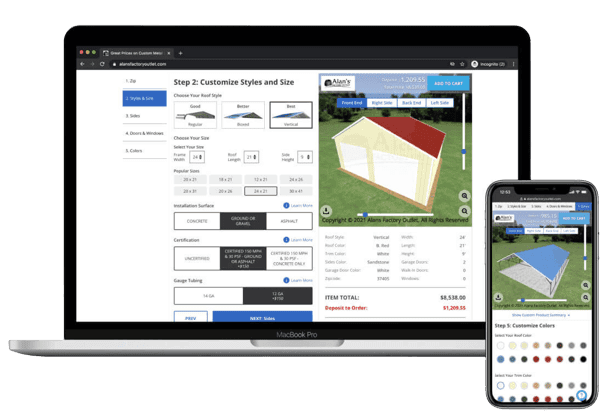

Design Your Next Building on a Strong Foundation

Even with a strong and stable foundation, problems can still arise if your building is improperly assembled or installed. Using our 3D Customizing Tool below, you can easily design and purchase your dream structure. Once purchased, our skilled team will deliver and install your custom building for free.