Quonset hut buildings are durable, arch-style metal structures made from corrugated steel, originally developed for military use during World War II. Today, they serve a wide range of purposes, from garages and storage units to workshops and even homes. Their curved design creates a clear-span interior with no support beams, maximizing usable space and simplifying construction.

Whether you’re planning a DIY build or seeking a cost-effective solution for commercial or agricultural needs, Quonset huts can offer long-term value with minimal maintenance. Their all-steel construction holds up well in harsh weather, making them a smart choice for rural and suburban properties.

In this guide, you’ll learn everything from Quonset hut types and materials to pricing, assembly, and comparisons with other metal buildings, so you can confidently choose the best structure for your needs.

History of Quonset Huts

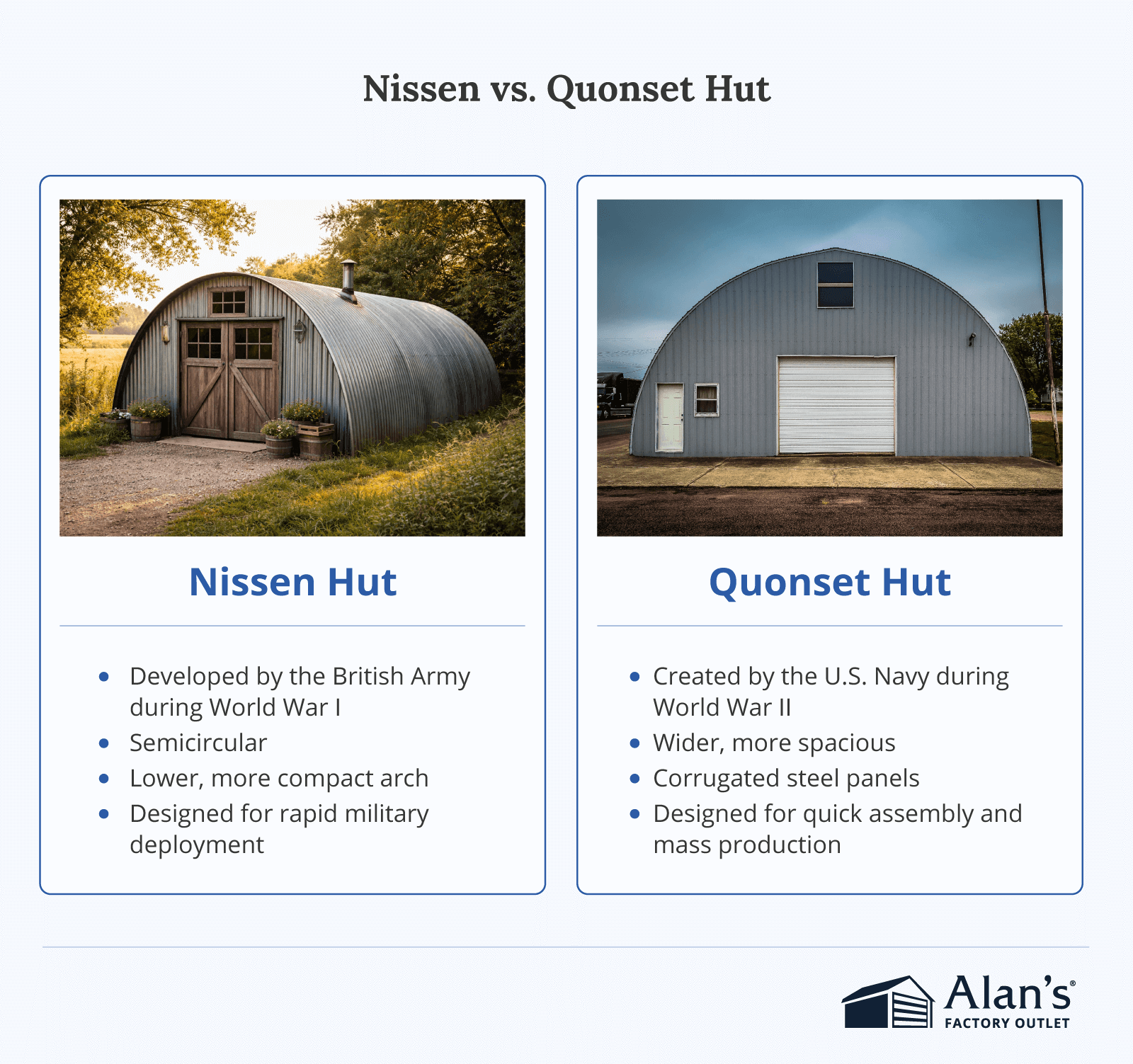

The Quonset hut traces its origins back to the Nissen hut, which was developed by the British Army during World War I. The Nissen hut’s semicircular design influenced future innovations in military housing and temporary structures.

During World War II, the U.S. Navy created the Quonset hut at Quonset Point in Rhode Island as a lightweight, easy-to-assemble shelter. Unlike their wartime predecessors, modern Quonset huts have been significantly improved for civilian use, offering better mass production, enhanced durability, and increased versatility in size and configuration.

Key Characteristics of a Quonset Hut

Quonset huts are known for a few distinct features that make them a smart, long-term building solution:

- Curved, open-span design. The signature arch building shape maximizes interior space and sheds snow or rain efficiently.

- Low-maintenance materials. Galvanized steel resists rust, pests, and fire, reducing upkeep needs over time.

- Long-lasting durability. These steel structures are built to handle harsh weather while maintaining structural integrity.

- Flexible size options. Available in a wide range of widths and lengths, with models suited for everything from backyard storage to full-scale commercial use.

Types of Quonset Hut Models

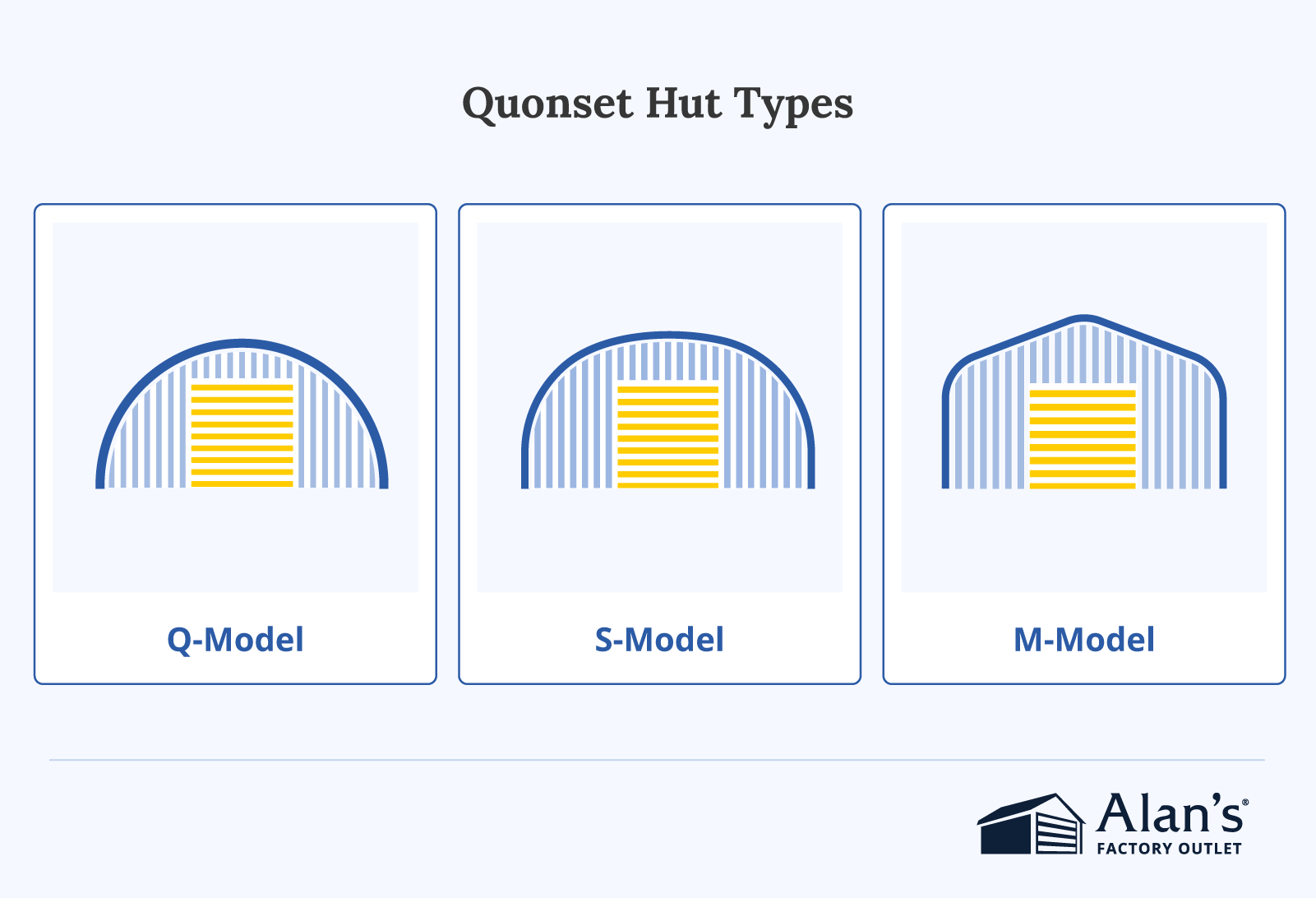

Choosing the right Quonset hut model starts with understanding the structural differences that affect performance and interior space. The three most common types below each offer specific benefits depending on your needs and location.

| Comparison of Common Quonset Hut Models | ||||

|---|---|---|---|---|

| Model | Arch design | Sidewalls | Best for | Performance features |

| Q-Model | Full semi-circular arch | None | High-wind areas | Strong wind resistance due to curved shape |

| P-Model | Pitched roof with straight sides | Full vertical sidewalls | Taller storage or workspaces | Increased interior height and clearance; higher cost |

| S-Model | Arched roof with straight sides | Full vertical sidewalls | Areas with high wind and snow | Combines wind/snow durability with more usable interior space |

Common Uses for Quonset Huts

Quonset huts are used across a wide range of settings thanks to their versatility, durability, and open interior design. From backyard workshops to full-scale commercial storage, these steel structures adapt easily to different needs and environments.

Residential & Personal Use

Many homeowners use Quonset hut homes and buildings as garages, DIY workshops, hobby studios, and even small cabin-style residences or tiny homes. The unobstructed interior space makes it easy to create custom layouts that match lifestyle or project needs.

Adding insulation improves energy efficiency, especially in climates with extreme weather conditions. These structures also offer customizable doors, windows, colors, and ventilation options to personalize the design while maintaining simplicity and function.

Agricultural, Business & Storage Use

Quonset huts serve as durable storage buildings for farms and small businesses alike. Common uses include sheltering hay, equipment, vehicles, and inventory, with many owners using them as general-purpose outbuildings or commercial storage units.

Farmers and business owners often choose this type of metal building kit because it’s a cost-effective, long-term building solution that performs well in challenging environments. Their strength, flexibility, and speed of assembly make them ideal for growing operations.

Quonset Hut Features & Components

The performance and longevity of a Quonset hut depend on several core components, including the quality of materials, structural design, and compliance with local building codes. Choosing the right combination of coatings, steel gauges, and engineering specs ensures your steel building can withstand local weather conditions and meet long-term use goals.

Materials & Coatings

Below is a summary of the key materials and coatings used in high-quality Quonset hut construction.

| Component | Description | Benefits |

|---|---|---|

| Galvanized steel | Steel coated with a layer of zinc | Rust-resistant, cost-effective, and durable for most climates |

| Galvalume | Steel coated with zinc and aluminum | Offers superior corrosion resistance: up to 10 to 25 years of longer lifespan than galvanized steel |

| Steel gauge | Thickness of the steel panels | Lower gauge numbers (e.g., 12-gauge) are thicker and more durable; ideal for snow loads or high winds |

Endwalls, Sidewalls & Openings

Quonset huts offer a variety of configurations for endwalls and sidewalls to suit different needs:

- Endwall options. Choose between fully open, solid, or partially enclosed endwalls depending on access, visibility, and climate requirements.

- Customizable features. Add doors, windows, and ventilation systems to improve airflow and usability without compromising structure.

- Sidewall height. Taller sidewalls can increase interior clearance and make the arch design more practical for vertical storage or tall vehicles.

These elements allow you to adapt building kits for anything from simple sheds to complex workshops.

Engineering & Building Codes

Every Quonset hut must meet engineering standards based on its installation site. This includes:

- Wind ratings. Coastal areas or tornado-prone zones, such as parts of Florida, may require designs rated for high wind speeds.

- Snow loads. Regions with heavy snowfall, like northern Rhode Island, demand higher load-bearing capacity for roof panels and endwalls.

- Code compliance. Local building codes may dictate foundation types, anchoring methods, and minimum structural performance metrics.

Choosing a vendor that offers certified engineering for your location ensures your steel building will pass inspections and perform as expected in all weather conditions.

Quonset Hut Prices & Cost Factors

Quonset hut prices typically range from $10 to $20 per square foot without installation costs, depending on size, steel gauge, finish, and add-ons. The following table breaks down sample Quonset hut sizes and how square footage translates into cost. Final costs vary based on steel gauge, finish, and optional upgrades like insulation or ventilation.

| Estimated Quonset Hut Costs by Size and Features | ||||

|---|---|---|---|---|

| Size category | Dimensions | Square footage | Estimated base cost | Notes |

| Small | 10’×12′ | 120 sq. ft. | ~$1,200 | Basic storage; lowest-cost option at $10/ft² |

| Medium | 30’×30′ | 900 sq. ft. | ~$13,500 | Workshop-sized with moderate upgrades at $15/ft² |

| Large | 40’×60′ | 2,400 sq. ft. | $24,000–$30,000+ | Fully featured with insulation, ventilation, or thicker steel |

For real-time pricing, see Alan’s Factory Outlet’s metal building price page.

What Affects the Price of Quonset Huts?

Several factors directly impact how much you’ll pay for a Quonset hut:

- Square footage. Larger buildings require more materials and labor, increasing the total cost, though the cost per square foot may drop.

- Steel gauge. Thicker panels (e.g., 12-gauge vs. 14-gauge) cost more but offer stronger structural performance.

- Optional upgrades. Add-ons like insulation, ventilation, framed openings, or custom paint can add several hundred to several thousand dollars, depending on scale.

These variables make Quonset huts highly customizable, but it’s important to balance features with budget for a truly cost-effective build.

Quonset Hut Kit Costs vs. Fully Built Structures

Choosing a Quonset hut kit for DIY assembly can significantly reduce total project costs. Many prefab kits come with all the necessary components for installation, and DIY builders can save on labor by handling the project themselves. This makes the Quonset hut kit a practical option for those with basic construction experience or access to local help.

However, professional contractors may be necessary for larger or more complex builds, especially when working in areas with strict code enforcement or tough weather conditions. While hiring a builder increases upfront costs, it may ensure faster assembly, better compliance, and long-term peace of mind.

How to Build a Quonset Hut

Assembling a Quonset hut is a straightforward process that many do-it-yourself builders can handle with basic tools and preparation. Still, every Quonset hut building project requires thoughtful planning, especially when it comes to choosing a good foundation, following engineering specs, and taking proper safety precautions. Always follow the manufacturer’s building kit instructions and wear proper safety gear throughout the process.

Here are the basic steps to build a Quonset hut:

- Prepare the site and foundation. Clear and level the area, then pour a concrete foundation or set piers based on your engineering requirements.

- Lay out and anchor the base rails. Align and secure the base of the structure to the foundation to provide a stable frame.

- Assemble the steel arch panels. Begin bolting together the curved panels on the ground in sections according to the Quonset hut building instructions.

- Raise and bolt the arches. With help (or lifting equipment), stand the assembled steel arches and bolt them into position sequentially.

- Secure endwalls and openings. Attach pre-framed endwalls, including any windows, doors, or vents specified in your building kit.

- Add weatherproofing and insulation. Seal seams as needed and install insulation if desired for temperature or moisture control.

In terms of tool requirements, you’ll typically need a socket wrench set, ladders or scaffolding, a drill/driver, and safety gear like gloves and eye protection. Some larger builds may require lifting equipment.

Comparing Quonset Huts to Other Metal Structures

Quonset huts offer unique advantages when compared to traditional metal buildings and pole barns, especially in terms of assembly time, cost, and structural resilience. Here’s how they stack up across key categories:

| Feature | Quonset hut | Traditional metal building | Pole barn |

|---|---|---|---|

| Cost | Lower due to fewer parts and faster build | Moderate to high | Moderate, varies by wood cost |

| Durability | High — all-steel, weather-resistant | High — steel frame with vertical panels | Lower — wood prone to decay or pests |

| Assembly | DIY-friendly; bolt-together arches | Requires more framing steps | Easier framing but labor-intensive |

| Interior space | Clear-span, no internal supports | May have interior supports | Columns may interrupt floor plan |

| Best for | Budget builds, rural properties, storage | Commercial, complex storage needs | Agricultural use in dry/moderate climates |

Quonset Hut vs. Traditional Metal Buildings

Quonset huts are generally easier to assemble than traditional straight-wall metal buildings, thanks to their pre-engineered steel arch design. While both offer amazing durability, Quonset huts stand out for faster DIY assembly and lower cost. However, traditional metal buildings offer more vertical wall clearance and are better suited for custom commercial layouts or large-scale storage.

Quonset Hut vs. Pole Barns

Pole barns use wood framing, which may be more familiar to some builders but comes with long-term durability concerns in humid or pest-prone regions. Quonset huts, by contrast, feature all-steel construction that holds up better in harsh weather conditions and requires less maintenance. While pole barns can be cheaper upfront, Quonset huts offer better longevity and structural resilience over time.

Where to Buy a Quonset Hut

Quonset huts are sold primarily through specialized online retailers and direct-from-manufacturer websites. While they offer durable prefab kits, you may prefer the expanded design flexibility and vertical clearance offered by a metal building from Alan’s Factory Outlet.

Whether you’re purchasing a Quonset hut or a custom metal building, prioritize vendors that provide:

- Certified engineering documents to meet local building codes

- Transparent pricing with itemized quotes and customization options

- Detailed material specs, including steel gauge, coating type (e.g., galvanized or galvalume), and load ratings for snow and wind

If you’re looking for a fully customizable alternative to a Quonset hut, try our 3D Carport & Metal Garage Builder to design a structure that meets your exact specifications.

Free Delivery and Installation in 21 States

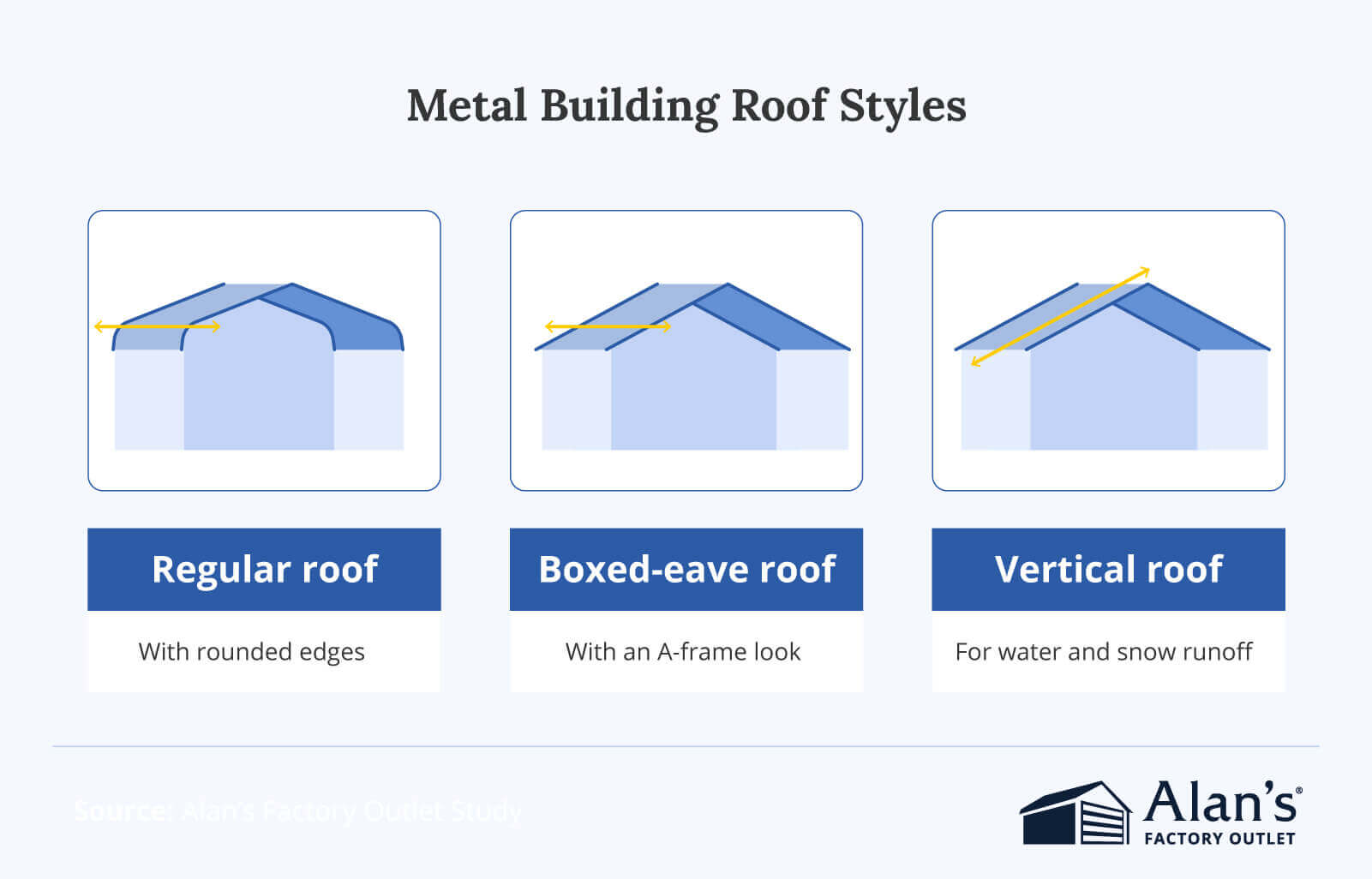

While Quonset huts use a curved steel arch, many buyers ultimately choose traditional metal buildings for greater design flexibility. One of the biggest differences comes down to roof style, which affects appearance, interior space, and performance in different climates.

Metal Building Roof Styles We Offer

In addition to Quonset huts, Alan’s Factory Outlet also offers customizable steel buildings with three durable roof styles, each suited to different climates and needs:

- Regular rolled-edge roof. Our most affordable option, this roof features a curved shape with rounded edges that provides good coverage for areas with mild weather. It’s a common pick for basic carports and light-duty storage.

- Boxed-eave roof. This style has horizontal roof panels and a cleaner, A-frame look that resembles traditional home roofing. It’s ideal for regions with moderate climates and works well for garages and workshops, though it may need occasional leaf clearing in fall.

- Vertical roof. With vertically aligned panels that allow rain and snow to slide off easily, this is the best option for locations with heavy precipitation or strong winds. Its structure also offers a sleek residential look and excellent long-term performance.

Want to compare these and other customization options visually? Use our 3D metal building builder to design and customize your ideal carport, garage, or metal building in minutes.

Looking for an Alternative to a Quonset Hut?

Quonset huts are a popular arch-style option, but many buyers end up choosing traditional steel buildings for more design flexibility, easier interior use, and more roof style choices.

At Alan’s Factory Outlet, you can customize a metal building with the roof style, dimensions, and openings that fit your needs — and get up-front pricing. Use our 3D Builder to compare options and get a quote in minutes. We also offer free delivery, with free installation available in 21 states.