Metal Building Insulation Types, Cost & Benefits

Insulation enhances comfort in metal buildings, especially in colder weather. If you’re preparing for winter, you might wonder if insulation is necessary, which type is most effective, and the related costs.

This article provides the essential information to help you decide whether to insulate your metal building and which insulation type to choose.

4 Key Benefits of Insulating Your Metal Building

No matter what kind of metal building you’ve got, insulation offers significant advantages. It enhances usability, protects your belongings, and increases property value. Below, we explore these key benefits in more detail.

Prevents Moisture Buildup

Insulation is essential for controlling moisture in metal buildings, reducing the risk of condensation that can cause rust and damage. By slowing down thermal bridging, insulation helps prevent harmful moisture accumulation.

Maintains Interior Temperature

Proper insulation is essential for regulating temperature, keeping heat inside during winter and blocking it out in summer. This ensures a comfortable environment and reduces energy costs, especially in heated spaces like garages.

Reduces Noise Levels

Temperature control isn’t the only benefit. Insulating your metal building also dampens noise, making it perfect for environments where loud machinery is used, such as workshops or garages.

Tubing

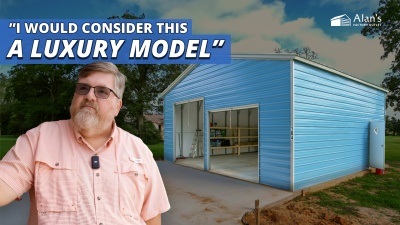

Adding insulation to a metal structure, like a garage, significantly enhances its resale value. It increases functionality and comfort, making the space more appealing and usable year-round.

3 Metal Building Insulation Types + Sizes and Cost

With so many different kinds of insulation on the market, it can be tricky to decide which type of metal building insulation fits your budget and needs best.

Comparing Insulation Types

Industry standards measure insulation by its R-value, or its ability to resist heat flow. Look for a higher R-value when you want more protection against the transfer of heat.

Let’s compare three common types of insulation for metal buildings along with their average cost. (Note that cost figures are subject to change.)

| Double Bubble | Woven | Spray Foam | |

|---|---|---|---|

| R-Value | 1 | 17 | 3.8-7 (per inch) |

| Thickness | 0.25” | 0.688” | Varies |

| Price/Sq. Ft. | $1.50 | $3.00 | $2.70 – $7.20 |

Double Bubble

Double bubble insulation features a silver backing that faces the building’s sheeting, while the visible side is white. It primarily controls moisture by preventing condensation on interior surfaces but offers minimal temperature regulation.

Double bubble is the least expensive and least protective type of insulation.

Woven

Woven insulation combines aluminum foil, bubble material, and woven fabric, resulting in an R17 rating. It provides better temperature control, making it a superior choice for metal buildings.

We recommend woven insulation as the optimal option for insulating metal buildings because it offers superior heat reflection, thermal resistance, and durability.

Spray Foam

Spray foam insulation is a more customizable option because it can be applied in odd shaped structures and tight spaces at almost any thickness. This type of insulation comes in two forms—open cell or closed cell.

Open-cell insulation isn’t recommended for very wet or humid climates because it can allow moisture to seep through, leading to hidden corrosion on metal walls.

Closed-cell insulation is water-resistant and suitable for areas with potential water contact. However, it is significantly more expensive than open-cell, costing over twice as much as other top insulation options.

Although water-resistant, closed-cell insulation can trap moisture if:

- Applied on a damp surface.

- Applied in a way that causes condensation.

- It traps water leaking in from the outside.

For buildings in drier climates, spray foam insulation, especially closed-cell, is an excellent option for enhancing insulation in metal structures.

Oil canning is a possible risk with spray foam insulation. As the spray foam cools and cures, it begins to shrink, which can cause the building’s metal panels to pull inward if they’re too large, weak, or just unsupported.

Prevent oil canning by bracing your walls before insulating them.

Free Delivery and Installation in 21 States

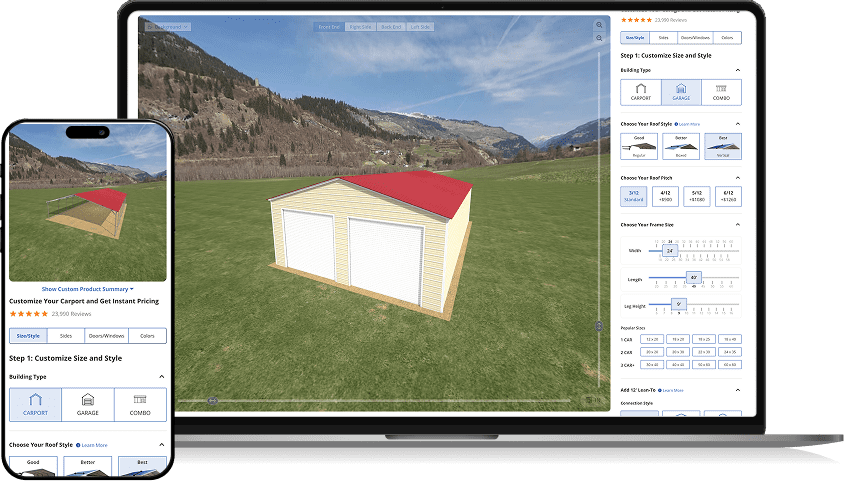

Get a Custom Metal Building at Unbeatable Factory-Direct Prices

Instant Online Pricing

Exact price online for metal buildings—no calls, no forms.

Free Delivery & Installation

We deliver and install at no extra cost in our service areas.

Certified Quality

U.S.-made steel, 1-year workmanship warranty.

100,000 Satisfied Customers

23 Years of factory direct prices

How to Determine Insulation Needs

Accurately calculating your insulation requirements is crucial, whether you’re insulating a metal shed, garage, workshop, or any other structure. The first step is determining which areas need insulation.

Where to Insulate

Insulating the roof and walls of your metal building is essential for protecting against temperature fluctuations and moisture buildup. Cold winds can cool the metal panels, causing condensation on the inside if the roof and walls aren’t properly insulated.

While insulating the floor and foundation provides additional protection, it is less critical than insulating the walls and roof, as most heat loss occurs through those areas.

Ensure that your metal building’s windows and doors are well-insulated and sealed to prevent air leaks, which can undermine the effectiveness of your insulation.

How to Estimate the Cost of Your Insulation

Determining the cost of insulation for a metal building requires calculating the roof, sides, and ends separately. Here’s a step-by-step guide:

Calculate Your Insulation Cost

Roof

(Width + 2′) x Frame Length

x Price per Sq. Ft.

Sides

Height x Frame Length x 2 (for both sides) x Price per Sq. Ft.

Ends

(Height + 2′) x Width x 2 (for both ends) x Price per Sq. Ft.

(Width + 2′) x Frame Length

x Price per Sq. Ft.

Add 2 feet to the width to cover the gables on a sloped roof, which increases the surface area compared to a flat roof.

Height x Frame Length x 2 (for both sides)

x Price per Sq. Ft.

Multiply by 2 to account for insulating both sides of the building, ensuring full coverage and consistent protection.

(Height + 2′) x Width x 2 (for both ends)

x Price per Sq. Ft.

Add 2 feet to the height for extra coverage on the ends. Multiply by 2 because there are two ends to insulate.

Example Calculation

For a building with a frame size of 12′ x 20′, sides that are 10′ tall, and using Double Bubble insulation ($1.50 per sq. ft.), the cost would be:

| Roof | (12′ + 2′) x 20′ x $1.50 | $420 |

| Sides | 10′ x 20′ x 2 x $1.50 | $600 |

| Ends | (10′ + 2′) x 12′ x 2 x $1.50 | $432 |

| TOTAL | $1,452 |

If your building is wider than 30′, a different pricing formula applies. Please contact us for a custom quote.

Reviews from Our Happy Customers

Alan’s Factory Outlet is a legitimate business with an A+ rating from the BBB.

Frequently Asked Questions

Budget insulation can help with moisture control but not temperature control or long term. Investing in better insulation gives you better results and extends the life of your metal building.

Our insulation is added at time of installation. We do not recommend adding insulation after the building is constructed as modifications could void your warranty. If you’re interested in insulation options be sure to include it in your order from the start. Check out our Metal Building Insulation page for more info!

Do you have a general question?

Get quick answers to common questions in our Help Center, an extensive knowledge base available 24/7.

Visit Our Help CenterDo you need something specific?

Please fill out the form on this page, or call us at 1-800-488-6903 (M-F, 8-6 Eastern).

Contact Us